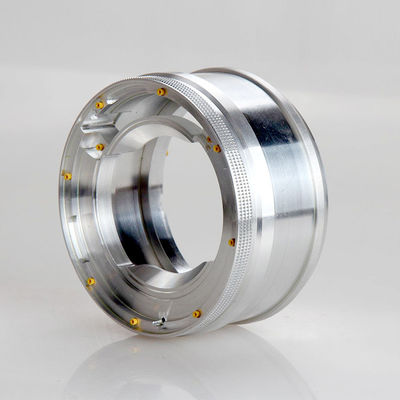

OEM Custom CNC Turning

Product Details

Product Name: OEM Custom CNC Turning

Machining Type: CNC Turning and Milling

Lathe Milling Type: CNC lathe +CNC machining

Material: Aluminum

Surface Roughness: Ra 0.8-Ra 3.2

DRW Format: DWG,Pdf for 2D; x_t,.igs,.stp for 3D

Tolerance: ±0.05mm, can be customized according to customer requirements, the most precise tolerance up to ±0.003mm

Proofing Period: 3-15 days

Managing Returned Goods: With quality problem or deviation from drawings

Production Cycle: According to the production quantity and product structure to determine

Surface Treatment: As machined

Origin: Dongguan, China

CNC Machining Part Capabilities

| Available Materials |

| Carbon Steel |

Stainless Steel |

Alloy Steel |

Tool Steel |

Titanium Alloy |

| Plastic |

Aluminum |

Copper |

Brass |

Bronze |

| Heat Treatment |

| Hardening |

Nitriding |

Carburizing |

Laser Quenching |

QPQ |

| Surface Finish |

| Zinc Plating |

Chrome Plating |

Chrome Plating |

Passivation |

Tin Plating |

| Silver Plating |

Gold Plating |

Anodizing |

Hard Anodizing |

PTFE Impregnated Hard Anodizing |

| Painting |

Powder Coating |

PTFE Coating |

Brushing |

Polishing |

What is CNC Turning

CNC machining has rapidly dominated the manufacturing industry in recent years due to its high precision and repeatability. With several CNC technologies available today, understanding the CNC machining basics will help you distinguish their features. One of these innovative technologies is CNC turning.

It involves removing materials from a rotating rigid workpiece by using a non-rotating cutting tool of a turning center or lathe. The CNC turning process can produce components with different shapes and sizes based on the type of turning operation.

CNC turning is a highly precise and efficient subtractive machining process that works on the principle of the lathe machine. It involves placing the cutting tool against a turning workpiece to remove materials and give the desired shape.

The turning center or lathe stays secured while the raw material rotates at high speed. As the workpiece rotates along a dual CNC turning machine axis movement, a single-point cutting tool helps to shape the material. Computer programs help to control the turning center or lathe, ensuring the production of meticulously precise components.

People confuse CNC turning and milling, but they are different processes. CNC milling and most other subtractive CNC processes often secure the workpiece to a bed while a spinning tool cuts the material. In contrast, CNC turning uses a reverse process that rotates the workpiece while the cutting bit remains static.

CNC Turning of Rotary Body Slots

1. Single row slot cutting: for annular slots with small width and depth dimensions, the cutting tool with equal width can be used to cut and cut the groove once. Generally, the tool is positioned rapidly along the z-axis direction and is processed along the X-axis direction. After cutting into the bottom of the groove, the tool can be stopped for a short time by using the pause instruction to trim the shape accuracy of the bottom of the groove.

2. Deep slot turning: the cutting route of deep groove shall adopt the method of sub-feed. After cutting into the workpiece at a certain depth, the cutter shall stop and return to a certain distance, so as to achieve the purpose of chip cutting and chip removal and avoid the phenomenon of tying and breaking the cutter. Note that the processing route only moves in radial (X direction) and back.

3. Wide-slot turning: when the precision requirements of turning side and groove bottom are both high, the method of row knife should be adopted for rough turning. Then, the fine cutting groove shall be rolled from one side of the groove to the groove bottom. When determining the finishing route, pay attention to the change of the cutter location. The distance of axial movement is not equal to the width of the groove, but the difference between the bottom of the groove and the width of the cutter.

CNC Machining Parts Order Procedure

FAQ

Q: How do you pack the products?

A: Normally as the export standard packaging or as your requirement.

Q: Do you provide design drawings service?

A: We mainly customize according to the drawings or samples provided by customers. For customers who don't know much about drawing, we also provide design and drawing services. You need to provide samples or sketches.

Q: Is it customized available?

A: Yes, according to the detailed drawing you provided.

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: How to enjoy the OEM services?

A: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!