Precision Aluminum CNC Turning-Milling Service

Product Details

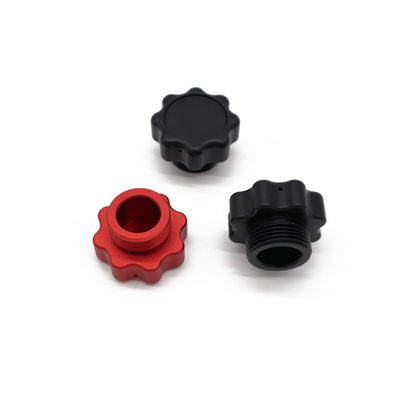

Product Name: Precision Aluminum CNC Turning-Milling Service

Machining Type: CNC Turning and Milling

Lathe Milling Type: CNC lathe +CNC machining

Material: Aluminum

Surface Roughness: Ra 0.8-Ra 3.2

DRW Format: DWG,Pdf for 2D; x_t,.igs,.stp for 3D

Tolerance: ±0.05mm, can be customized according to customer requirements, the most precise tolerance up to ±0.003mm

Proofing Period: 3-15 days

Managing Returned Goods: With quality problem or deviation from drawings

Production Cycle: According to the production quantity and product structure to determine

Surface Treatment: Beadblasting and anodizing

Origin: Dongguan, China

CNC Machining Parts Details

| Material |

Aluminum |

Brass |

Copper |

Carbon steel |

Stainless Steel |

| Engineering Plastic |

Titanium |

|

|

|

| Process |

CNC Milling |

CNC Turning |

Secondary |

Laser Cutting |

Bending |

| Welding |

Punch |

Assembly |

|

|

| Finishing |

Anodized |

Chemical Oxidation |

Sand Blasting |

Plated |

Powder Coat |

| Wet Painting |

Black Oxide |

Heat Treatment |

|

|

| Tolerance |

ISO2768 -1&-2 |

ISO 286-1&-2 |

DIN 7168 |

ASME-Y14.5M |

|

| Hazardous Substances |

RoHS |

Reach |

EN71 |

|

|

| Others |

Client Drawing & Sample |

Types of CNC Turning Machine

You can use four major types of CNC turning machines for your project. They include:

Horizontal Turning Centers

These are enclosed machines that integrate both drilling and milling capabilities. This turning center uses a horizontally-oriented spindle and tools that are mounted above the rotating workpiece. The cutting tools cut across the material and use gravity to pull chips away as it is with milling. The chips go down into the bed for easier removal.

Vertical Turning Centers

A vertical turning center combines the horizontal turning center with the CNC mill. The design is such that the rotating chuck is set flat on the ground, ensuring the machining of large pieces at lower revolutions per minute (RPMs). In this case, the tool turret approaches from the side. There are also inverted vertical turning centers with the spindle and chuck in reversed positions.

Horizontal Lathes

Horizontal lathes have all the features of a conventional lathe. The only difference is that computer programs control them. Also, their primary operations are turning and boring.

Vertical Lathes

Unlike a horizontal lathe, a vertical lathe holds the workpiece from the bottom before spinning it. This is a good option for machine shops with space constraints. Furthermore, it is the ideal option when working on heavy workpieces.

Why Choose Us?

- Reasonable price, excellent service. With many enterprises to establish long-term cooperative relations, many years of non-standard parts and machine experience, so that you can get more satisfactory products.

- Professional production technology and strict quality control. We are experienced in the production, installation and service of automatic parts. Strict quality management can guarantee the production schedule and quality requirements.

- Reasonable design Suggestions. With many years of experience in making non-standard parts, we have rich experience in proposing design modification suggestions and solutions according to customers' requirements.

- Perfect after-sales service. For the problems of products, we can timely communicate with customers, whether design problems or quality problems, we can timely put forward solutions to solve problems, for customers to solve the problems.

CNC Machining Process Flow

FAQ

Q: What Is The MOQ?

A: Usually, we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: What extra service you can provide?

A: We can not only machine the parts,we also can do surface finishes, such as anodizing, electronic plating, powder coating, painting, surface polishing service etc. We also provide assembly service for the parts if necessory.

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: About drawing confidentiality

A: The processed samples and drawings are strictly confidential and will not be disclosed to anyone else.

Q: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!