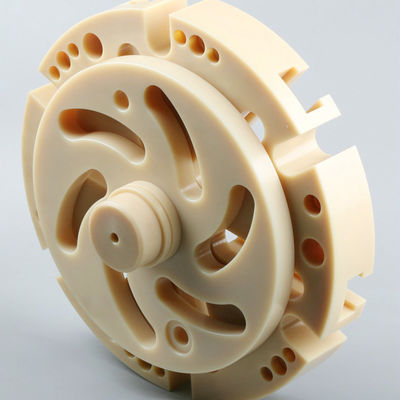

PEEK CNC Turning Parts

Product Details

Product Name: PEEK CNC Turning Parts

Machining Type: CNC Turning

Machining Accuracy: High

Lathe Milling Type: CNC lathe +CNC machining

Material: PEEK

Tolerance: ±0.05mm, can be customized according to customer requirements, the most precise tolerance up to ±0.003mm

Proofing Period: 3-7 days

Production Cycle: According to the production quantity and product structure to determine

Surface Treatment: As machined

Origin: Dongguan, China

CNC Machining Product Description

| Name |

Custom high Precision Aluminum Stainless Steel CNC Milling Turning Parts CNC Turning Machining Service |

| Parts Material |

Aluminium Alloy, Carbon Steel, Stainless steel, Copper, Brass, Nylon, Plastic(Customized Material) |

| CNC Machining |

CNC turning, milling, Swiss type machining, CNC center, 3-4-5 axis machines machining |

| Surface Treatment |

Anodizing, Polishing, Electroplating, Heat Treatment, Spray Paint, Sand Blasting, Silk Screen, etc |

| Testing Equipment |

Salt Spray Test, Hardness Tester, Coating Thickness Tester, Two Dimensions Measuring Instrument |

| Lead Time |

Generally, sample time is 3-10 Days, delivery time of bulk order is more than 15 days |

| Tolerance and Roughness |

Size Tolerance: +/-0.01 - 0.02mm, Roughness: Ra0.2 - Ra3.2 (Custom Size Requirements) |

| Design Files |

PDF, DXF, ISG, STEP, X-T, High Resolution IPJ |

| Pacakge |

Standard package/Pallets or container/Customized specfification |

| Cargo Shipment |

Express(DHL,Fedex,UPS, TNT ), Air shipment+Local Express Delivery, Ocean Shipment |

| Payment Term |

Sample: Full payment at advance. Bulk: 40% or 50% advanced deposit, balance before shipment |

CNC Turning

The main difference between this process and milling is that the workpiece is mounted on a chuck which then spins continuously against a stationary cutting tool. Because of this, the cutting tool does not chip against the surface but rather continuously shaves material away, like paring an apple with a knife.

This is ideal for making any circular features, including grooves, stepped diameters, bores, tapped and threaded holes, etc. There will also be a characteristic, regular pattern left on the workpiece, which will necessarily be circular and at right angles to the long axis on which it was turned.

A good CNC lathe with the right cutting tool can also achieve a surface Ra of 0.4. Although equal in absolute value to that of milling, the surface texture will nonetheless have a different pattern of more closely spaced scratches, which will give it the appearance of being much "smoother". This is very important to consider when specifying an Ra value – every process has its own special mark that it leaves on the workpiece, and they can look and feel very different.

CNC Grinding

Here, the workpiece is held rigid, either horizontally or vertically. An abrasive grinding wheel is passed over the surface, shaving down high spots and erasing any patterns. The effect is non-directional so the surface appears very uniform. This process generally produces the flattest and smoothest surface texture, aside from meticulous and specialized hand lapping.

Grinding with the correct abrasive, lubricant and cutting speed can achieve a surface Ra of 0.05 or better. It only works on flat surfaces that don' t have any features that would interfere with the movement of the grinding wheel.

Our Capability of CNC Turning

Regarding the production capability of CNC lathe machined parts which are with linear appearance. When CNC machining, the raw material rod (usually made of metal or plastics) will rotate at high RPM. Then, a cutting tool will traverse along X, Y or Z axis motion to manufacture precise dimensions. CNC turning shaft is one of the most common spare parts, which is often used in various market sectors, such as multi-function printer, scanner, driving shaft for torque transmission, etc. Alloy steel with case hardened or carburized for better wearing resistance can meet requirement of high torque transmission purpose.

Surface Finish for your CNC Machining Parts

FAQ

Q: If I need the parts urgent, can you help?

A: Yes, we are here to help. Production time is flexible. If you need the parts urgent, please tell us the delivery time you need. We will do our best to adjust the production schedule priority.

Q: Where can I get product&price information?

A: Send us an inquiry in this page or e-mail, we will contact you after upon receipt of your mail.

Q: How can you guarantee the quality?

A: Quality is our culture. Quality control department set up control plan before starting the project, and all PPAP report will be provided to the whole process.

Q: What kind of production service do you provide?

A: CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), simple assembly and various metal surface treatment.

Q: Can you advise on suitable materials for us?

A: Yes, we are very knowledgeable and can recommend the best grade materials for your application.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!