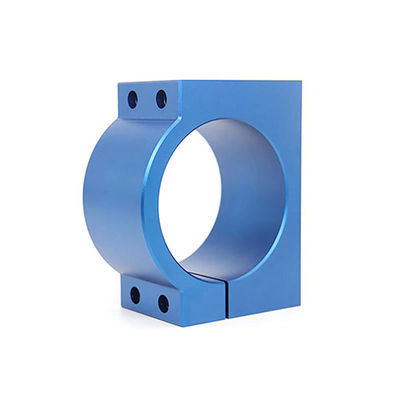

OEM CNC Milling Part

Product Details

Poduct Name: OEM CNC Milling Part

Material: Aluminum

Surface Treament: Anodizing

Size: Customized

Process Machine: CNC machining center

Trade Terms: EXW

Proofing Time: 5-10 Days

Production Time: It depends on the structure and qty of the parts

Tokerance: ±0.05mm

Application: Machine

Origin: Dongguan, China

CNC Machining Product Description

| Name |

Custom high Precision Aluminum Stainless Steel CNC Milling Turning Parts CNC Turning Machining Service |

| Parts Material |

Aluminium Alloy, Carbon Steel, Stainless steel, Copper, Brass, Nylon, Plastic(Customized Material) |

| CNC Machining |

CNC turning, milling, Swiss type machining, CNC center, 3-4-5 axis machines machining |

| Surface Treatment |

Anodizing, Polishing, Electroplating, Heat Treatment, Spray Paint, Sand Blasting, Silk Screen, etc |

| Testing Equipment |

Salt Spray Test, Hardness Tester, Coating Thickness Tester, Two Dimensions Measuring Instrument |

| Lead Time |

Generally, sample time is 3-10 Days, delivery time of bulk order is more than 15 days |

| Tolerance and Roughness |

Size Tolerance: +/-0.01 - 0.02mm, Roughness: Ra0.2 - Ra3.2 (Custom Size Requirements) |

| Design Files |

PDF, DXF, ISG, STEP, X-T, High Resolution IPJ |

| Pacakge |

Standard package/Pallets or container/Customized specfification |

| Cargo Shipment |

Express(DHL,Fedex,UPS, TNT ), Air shipment+Local Express Delivery, Ocean Shipment |

| Payment Term |

Sample: Full payment at advance. Bulk: 40% or 50% advanced deposit, balance before shipment |

Profile CNC Milling Processes

Before reaching the final machined part, it is first subdivided into different categories: roughing/semi-roughing, semi-finishing, finishing and superfinishing. The larger the component, the more types of operations are involved. It is very important to sub-categorize the operations of the machined workpiece so that you can maximize the full potential of the tools and parameters you will use.

Roughing-This operation is always the first stage of processing, usually starting from cutting the raw material block, so that the part is roughly close to the desired shape or contour, to leave enough metal inventory for further operations.

The semi-finishing-This process involves machining parts according to size requirements or removing remaining blanks on parts. Semi-finished parts can also be further processed to meet specific requirements for surface finish.

Finishing-this process is carried out after the semi-finishing operation. Finishing is to improve the surface finish of parts by removing obvious burrs and other surface defects. In this operation, high-performance tools must be used, as this will significantly affect the final appearance of the workpiece.

Super finishing-If the part requires a mirror finish or an ultra-smooth contour, the operation will proceed further to superfinishing. To this end, high-speed machining technology and high-precision tools are required.

Get to Know the Tools Used in CNC Milling Curved Surface

To obtain a smooth curved surface on the part being manufactured, circular end mills of different variants are used. These include round inserts, ball-end indexable end mills, and ball-end solid carbide. The circular contour tool is the first choice for contour machining applications because it does not leave obvious tool path marks.

Insert type end mills with round inserts-These tools usually have large tool diameters. Round-blade end mills are very suitable for roughing operations due to their high stability and impressive productivity.

Solid ball end mills-these end mills can leave a very good surface finish on the machined parts. Due to their structure, they may have low stability. This is why they are more commonly used for finishing rather than roughing.

Indexable head ball end mills-Indexable head end mills are similar to solid carbide end mills, but with replaceable cutter heads. These special tools have a detachable end that can be replaced when needed.

CNC Milling Process

FAQ

Q: How can I get a quotation from your company?

A: In order to quote you the CNC machining parts as soon as possible please provide us the following information to our email:

1) Detail drawings(CAD / PDF/ DWG/ IGS/ STEP)

2) Material

3) Quantity

4) Surface treatment

5) Any special packing or other requirements

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes. We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Q: How to contact sales person?

A: Please send us inquiry or e-mail directly. Or you can talk with us online by trademanager, skype, whatsapp, WeChat, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!