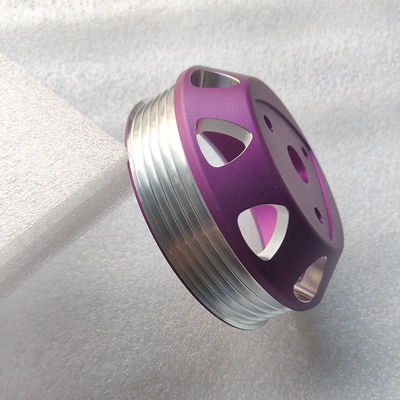

Precision OEM CNC Milling

Product Details

Poduct Name: Precision OEM CNC Milling

Material: Aluminum

Surface Treament: Anodizing

Size: Customized

Process Machine: CNC milling machine

Trade Terms: EXW

Proofing Time: 5-10 Days

Production Time: It depends on the structure and qty of the parts

Tokerance: ±0.05mm

Application: Automotive

Origin: Dongguan, China

Custom CNC Machining Part Service

| Name |

CNC Machining Parts |

| Available Materials |

Steel, Aluminum, Alloy, Brass, Copper, Bronze, Nylon, Acrylic, etc |

| Process |

CNC milling and turning, drilling, grinding, bending, stamping, tapping |

| Tolerance |

0.005mm~0.1mm |

| Surface Roughness |

Ra1.6-3.2 |

| DRW Format |

PDF/DWG/IGS/STP/X_T etc |

| Equipment |

CNC machining center, CNC turning, General milling machines |

| MOQ |

1pc |

| Machining Scope |

1). Equipment/Machinery

2). Medical & Technological parts

3). The Automotive/motorcycle parts

4). The telecommunication parts

5). The power tool parts

6). Bicycle parts

7). The agricultural parts

8). Hardware |

| QC System |

100% inspection before shipment |

| Payment Term |

T/T, PayPal |

| Surface Treatment |

Anodizing, zinc/chrome/nickel/silver/gold Plating, Polish, Sandblast, Brushing, Oxide, Silk Print, Laser engraving, Heat treatment, etc |

| Shipment Terms |

1) 0-100kg: air freight priority |

| 2) >100kg: sea freight priority |

| 3) As per customized specifications |

| Packing |

1. Prevent from damage.

2. As customers' requirements, in perfect condition.

3. Send the sample by express, 3~5 days door to door service. |

Thread CNC Milling Method for Machining Screws

Thread milling is the use of thread milling tools for the processing of large-hole threads, as well as the processing of threaded holes with difficult-to-machine materials. It has the following characteristics:

1. The tool is generally made of cemented carbide material, with fast speed, high thread milling precision and high processing efficiency;

2. The same pitch, whether it is a left-handed thread or a right-handed thread, can use a tool to reduce the cost of the tool;

3. The thread milling method is especially suitable for the thread processing of difficult-to-machine materials such as stainless steel and copper. It is easy to remove chips and cool, and can ensure the quality and safety of processing;

4. There is no tool front guide, which is more convenient to process blind holes with short threaded bottom holes or holes without undercuts.

Thread milling tools are divided into two types: machine-clamped carbide insert milling cutters and integral cemented carbide milling cutters. Machine-clamped tools can not only process holes whose thread depth is less than the length of the blade, but also can process holes whose thread depth is greater than the length of the blade. Holes; and solid carbide milling cutters are used to machine holes whose thread depth is less than the length of the tool.

Advantages and Disadvantages of CNC Milling

Advantages

Accuracy and Precision

CNC milling machines have higher accuracy and precision. Therefore, they can create parts according to their technical specification. As a result, they can mill parts with tolerances as tight as 0.0004. Also, being an automated process reduces the chances of human errors.

Fast and Efficient

Compared to conventional millers, CNC millers are fast and efficient. This is a result of their ability to carry many cutting tools (depending on the ATC), which aids effective tool-changing and efficient processes.

Large Compatible Material

The process is compatible with many compatible materials, e.g., plastic, composites, and metals. Therefore, CNC milling might be the perfect process once you have a block of material.

Disadvantages

Material Wastage

The process is subtractive, i.e., material removal occurs to form the desired part. Therefore, compared to other manufacturing methods such as 3D printing services, there is much material wastage.

High Level of Maintenance

CNC millers require a high level of maintenance to keep them functioning well. The machine is expensive. Therefore, maintenance is important.

Quality Control of CNC Machining Parts

FAQ

Q: How can I get a quotation from your company?

A: In order to quote you the CNC machining parts as soon as possible please provide us the following information to our email:

1) Detail drawings(CAD / PDF/ DWG/ IGS/ STEP)

2) Material

3) Quantity

4) Surface treatment

5) Any special packing or other requirements

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes. We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Q: How to contact sales person?

A: Please send us inquiry or e-mail directly. Or you can talk with us online by trademanager, skype, whatsapp, WeChat, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!