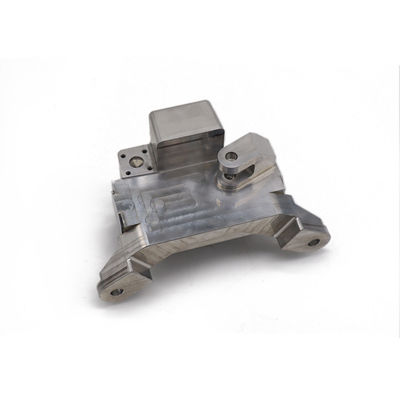

Custom CNC Milling

Product Details

Poduct Name: Custom CNC Milling

Material: Aluminum

Surface Treament: Anodizing

Size: Customized

Process Machine: CNC milling machine

Trade Terms: EXW

Proofing Time: 5-10 Days

Production Time: It depends on the structure and qty of the parts

Tokerance: ±0.05mm

Application: Equipment

Origin: Dongguan, China

CNC Machining Parts Details

| Material |

Aluminum |

Brass |

Copper |

Carbon steel |

Stainless Steel |

| Engineering Plastic |

Titanium |

|

|

|

| Process |

CNC Milling |

CNC Turning |

Secondary |

Laser Cutting |

Bending |

| Welding |

Punch |

Assembly |

|

|

| Finishing |

Anodized |

Chemical Oxidation |

Sand Blasting |

Plated |

Powder Coat |

| Wet Painting |

Black Oxide |

Heat Treatment |

|

|

| Tolerance |

ISO2768 -1&-2 |

ISO 286-1&-2 |

DIN 7168 |

ASME-Y14.5M |

|

| Hazardous Substances |

RoHS |

Reach |

EN71 |

|

|

| Others |

Client Drawing & Sample |

Type of CNC Milling Machine

There are many types of CNC millers, each with different attributes and costs. The most important factor determining the type of machine you use is the design complexity previously explained above.

CNC milling service sets the cost of milling machines at an hourly rate (sometimes with the operator’s cost). The service calculates the cost of using a milling machine from the purchasing cost and how long it should operate yearly. For example, in Europe, 3-axis machines cost around $40 per hour while 4-axis and 5-axis machines cost between $75 to $120 per hour.

However, there are situations where they can be less expensive. For example, Chinese CNC milling services such as Fifth Metal offer 3-axis machines for $8-$10 per hour and 5-axis machines for $30 per hour.

Applications of CNC Milling Technique

Milling is highly accurate, precise, and with high tolerance. Hence it has a wide range of applications. Below are some of its industrial applications.

Aerospace

Computer numerical control milling is applicable in making many aeronautic components using materials such as titanium and aluminum. These materials are lightweight and durable. Due to the high need for accuracy and precision, the process is considered suitable.

Automotive

The automotive industry uses milling machining due to the requirement for efficiency without losing accuracy. Therefore, it is suitable for products made using the process include interior panels, cylinder heads, drive axles, suspension components, exhaust parts, and gearboxes.

Agriculture

CNC milling machining is suitable for making general purpose parts and components such as gears and shafts, nuts and bolts, and flanges. Furthermore, it is suitable for both large-scale and short-term production capabilities.

Medical

Medical parts such as prostheses require precise and unique design. Therefore, CNC milling is the better method for such parts. The design is retained, and there is productivity and efficiency.

CNC Milling Parts Package and Delivery

FAQ

Q: What is the shipping method?

A: For engineering samples we will send out by international express service or by air. For mass-production, it depends on weight and volume, usually by air or by sea.

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes. We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Q: How to contact sales person?

A: Please send us inquiry or e-mail directly. Or you can talk with us online by trademanager, skype, whatsapp, WeChat, etc.

Q: What's kinds of information you need for a quote?

A: Kindly please provide the product 2D drawing with PDF or DWG format and 3D drawings with STEP or IGS or X_T format, and other requirements like: surface treatment, quantity...etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!