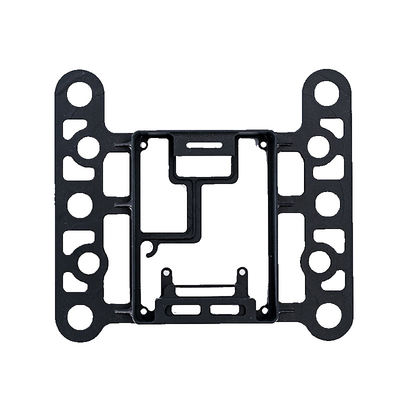

OEM Precision 5 Axis CNC Machining Parts

Product Details

Product Name: OEM Precision 5 Axis CNC Machining Parts

Material: Aluminum 7075

Surface Finish: Anodizing, surface treament as customers' requirement

Dimension: Customized

Process: CNC Milling

MOQ: 1 PCS

Delivery Time: The fastest 5-10days for sample and small volume, according to the volume to determine the delivery time

Delivery Terms: DHL, FEDEX, UPS, TNT, etc.

CNC Machining Parts Details

| Material |

Aluminum |

Brass |

Copper |

Carbon steel |

Stainless Steel |

| Engineering Plastic |

Titanium |

|

|

|

| Process |

CNC Milling |

CNC Turning |

Secondary |

Laser Cutting |

Bending |

| Welding |

Punch |

Assembly |

|

|

| Finishing |

Anodized |

Chemical Oxidation |

Sand Blasting |

Plated |

Powder Coat |

| Wet Painting |

Black Oxide |

Heat Treatment |

|

|

| Tolerance |

ISO2768 -1&-2 |

ISO 286-1&-2 |

DIN 7168 |

ASME-Y14.5M |

|

| Hazardous Substances |

RoHS |

Reach |

EN71 |

|

|

| Others |

Client Drawing & Sample |

5-Axis CNC Machining Configurations

As mentioned earlier, the movement of axes of the 5-axis manufacturing process depends on the instructions of the CNC program. There are fundamentally two CNC machining operation styles that work with 5-axis:

Trunnion Style

The trunnion-style machine works with the A-axis rotating around the X-axis and the C-axis rotating about the Z-axis. The movement of the table indicates the rotary axes. That is, both rotational axes are located within the table while the head remains stationary (Table/Table). Trunnion-style 5-axis CNC machines are suited to:

- Large work volumes

- Removal of heavy metal without the head moving out of position

- Better undercut capabilities

Swivel Rotate Style

The Swivel rotate style 5-axis CNC machine works with the B-axis rotating about the Y-axis while the C-axis rotates around the Z-axis. This movement differs from the Trunnion style because the table remains horizontal throughout the cutting process. As a result, it can support heavier components. Swivel rotate machines are suited to:

- Machining larger components

- Using shorter cutting tools

Aboout CNC Machining Process

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where raw material is removed with a variety of precision cutting tools to make a part or product. Advanced software is used to control the equipment according to the specification of your 3D design. Our team of engineers and machinists program the equipment to optimize cutting time, surface finish and final tolerance to meet your specifications. We use CNC machining not only to manufacture parts and prototypes but also to make mold tools.

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

1. Quick removal of large amounts of metal material

2. Highly accurate and repeatable

3. Suitable for many different kinds of substrates

4. Scalable volumes from one to 100,000

5. Low investment in tooling and preparation costs

6. Economical

7. Fast turnaround

FAQ

Q: What kind of payment does your factory accept?

A: T/T, Paypal.

Q: Do you test all your goods before delivery?

A: Yes, we have test machine and QC worker to do the test.

Q: How do you ship the goods?

A: We have our cooperation forwarder, they can deliver the goods to you in a short time at a competitive price, and you can ship by your own agent at your convenience.

Q: What raw material do you use?

A: stainless steel, carbon steel, mild steel, galvanized steel, aluminum alloy, brass, copper, Titanium, etc.

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: Can you strictly follow the tolerance on the drawing and meet the high precision?

A: Yes, we can, we can provide high precision parts and make the parts as your drawing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!