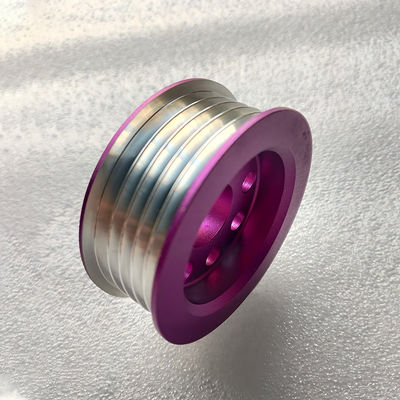

OEM Aluminum CNC Turning Parts

Product Details

Product Name: OEM Aluminum CNC Turning Parts

Machining Type: CNC Turning and Milling

Lathe Milling Type: CNC lathe +CNC machining

Material: Aluminum

Surface Roughness: Ra 0.8-Ra 3.2

DRW Format: DWG,Pdf for 2D; x_t,.igs,.stp for 3D

Tolerance: ±0.05mm, can be customized according to customer requirements, the most precise tolerance up to ±0.003mm

Proofing Period: 3-15 days

Managing Returned Goods: With quality problem or deviation from drawings

Production Cycle: According to the production quantity and product structure to determine

Surface Treatment: As machined

Origin: Dongguan, China

CNC Machining Part Description

| CNC Machining |

CNC turning, milling, Swiss type machining, CNC center, 3/4/5 axis CNC machining |

| Tolerance |

up to 0.005mm |

| Roughness |

Ra0.4 |

| Materials |

Stainless steel, aluminum, steel, brass, bronze,titanium, carbon steel, cooper, mild steel, plastic, nylon, POM, PP, PU, PET, PEEK, HDPE etc. |

| Treatment |

Anodizing, polishing, plating, heat treatment, hardening, electroplated, etc |

| Application |

3C electronics, electrical appliances, medical equipment, semiconductor laser devices, printing machinery, spare parts, vehicle production equipment, industrial machinery, aerospace, communications, optics, education, entertainment, health care, advertising and other industries. |

| Quote |

24h*7d online, quotes in 24 hours |

| Sample |

3-10 days |

What Is CNC Turning?

CNC machining has rapidly dominated the manufacturing industry in recent years due to its high precision and repeatability. With several CNC technologies available today, understanding the CNC machining basics will help you distinguish their features. One of these innovative technologies is CNC turning.

It involves removing materials from a rotating rigid workpiece by using a non-rotating cutting tool of a turning center or lathe. The CNC turning process can produce components with different shapes and sizes based on the type of turning operation.

CNC turning is a highly precise and efficient subtractive machining process that works on the principle of the lathe machine. It involves placing the cutting tool against a turning workpiece to remove materials and give the desired shape.

The turning center or lathe stays secured while the raw material rotates at high speed. As the workpiece rotates along a dual CNC turning machine axis movement, a single-point cutting tool helps to shape the material. Computer programs help to control the turning center or lathe, ensuring the production of meticulously precise components.

People confuse CNC turning and milling, but they are different processes. CNC milling and most other subtractive CNC processes often secure the workpiece to a bed while a spinning tool cuts the material. In contrast, CNC turning uses a reverse process that rotates the workpiece while the cutting bit remains static.

Surface Treament for CNC Turning Parts

FAQ

Q: What Is The MOQ?

A: Usually, we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: What extra service you can provide?

A: We can not only machine the parts,we also can do surface finishes, such as anodizing, electronic plating, powder coating, painting, surface polishing service etc. We also provide assembly service for the parts if necessory.

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: About drawing confidentiality

A: The processed samples and drawings are strictly confidential and will not be disclosed to anyone else.

Q: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!