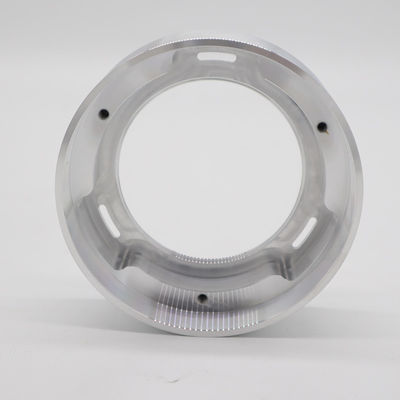

Aluminum CNC Turning Lighting Parts

Product Details

Product Name: Aluminum CNC Turning-Milling Lighting Parts

Machining Type: CNC Turning and Milling

Lathe Milling Type: CNC lathe +CNC machining

Material: Aluminum

Surface Roughness: Ra 0.8-Ra 3.2

DRW Format: DWG,Pdf for 2D; x_t,.igs,.stp for 3D

Tolerance: ±0.05mm, can be customized according to customer requirements, the most precise tolerance up to ±0.003mm

Proofing Period: 3-15 days

Managing Returned Goods: With quality problem or deviation from drawings

Production Cycle: According to the production quantity and product structure to determine

Surface Treatment: As machined

Origin: Dongguan, China

Surface Treatment for CNC Machining Part

| Aluminum Parts |

Stainless Steel Parts |

Steel Parts |

Brass Parts |

| Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

| Color Anodized |

Passivating |

Oxide black |

Chrome Plating |

| Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

| Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

| Brushing |

Electrophoresis black |

Carburized |

Powder Coated |

| Polishing |

Oxide black |

Heat Treatment |

|

Quality Assurance & Customer Satisfaction

To consistently exceed customer expectations, quality control and assurance is achieved through:

- Detailed records of incoming raw materials

- Detailed computer generated traveler tickets

- Analysis of root cause of non-conformances

- Fully equipped inspection department

- Multi-level incoming order review

- Fully equipped inspection department

- Periodic calibration and labeling of inspection tools

- Comprehensive written procedures and policies

- Designated areas for nonconforming parts

- Corrective actions to prevent recurrence of non-conformances

- Daily backup of electronic records stored in multiple locations

- Extensive electronic records of orders, customer communications, and inspection results

- Comprehensive software expert system advising customers of manufacturability issues

- Staff members being strongly encouraged to suggest improvements in methods, materials, and suppliers

The Process of Finishing an Order

Inquiry

Customer send the demands and requirements details ,including the part data( 2d/3d drawings with format of IGES, DXF, DWG, STP, PRT, )

Quote

Single parts we quote it in one day while project parts in 3-5 days based on the technical demands and function details. The quote will including the cost way (EX-WORK/FOB/CIF/DDU/DDP etc) and delivery time. It also show the payment term ( 50% for the deposit, the rest 50% before the shipping or 100% payment )

Order Released

For the new customer, they may make sample order before the batch one.

Whether the value low or high we will keep top quality and service. We are reliant partner for you.

Drawings Confirmation

Before the production schedule, our R&D department will analysis the data from our sales team,make sure they know their customer's requirements clearly and no important information missed.

Production Schedule and Control

There will be production schedule sheet for the order and make sure the delivery will on time. We will supply the machining process for customer if they need.

QC for the Finished Order

When it comes to the end of the production, QC staffs will check the products by the internal standard. We also can follow up customer's standard for some special projects.

Payment Check

According to the payment term clause, customer need to pay the rest of money before product shipped.

Shipping Arrangement

Air/ Sea freight or International express based on customer's demands.

Order Records Management

Data management and experience recorded.

Order Closed

CNC Machining Parts Show

FAQ

Q: What Is The MOQ?

A: Usually, we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: What extra service you can provide?

A: We can not only machine the parts,we also can do surface finishes, such as anodizing, electronic plating, powder coating, painting, surface polishing service etc. We also provide assembly service for the parts if necessory.

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: About drawing confidentiality

A: The processed samples and drawings are strictly confidential and will not be disclosed to anyone else.

Q: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!