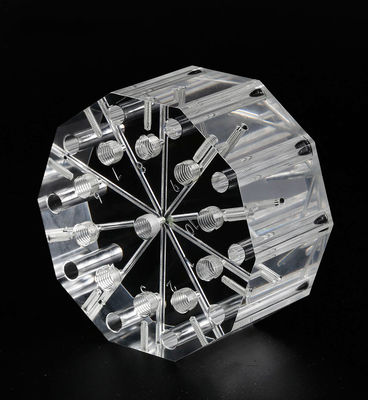

Precision CNC Machining Plastic Parts

Product Details

Product Name: Precision CNC Machining Plastic Parts

Material: Plastic

Process: CNC machining(turning, milling, drilling)

Surface Treatment: Polishing, sandblasting, anodizing, brushing, powder coating, electroplating, zinc plating, silk-screen

Tolerance: ±0.05mm

Quality control: 100% check before shipment

Drawing format: PDF/DWG/IGS/STP

Delivery: By DHL, FEDEX and so on

Term of Payment: 30% deposit when order, 70% before shipment

Trade Terms: FOB, CIF, EXW

High Precision OEM CNC Machining Parts Supplier

| Service |

CNC Turning, CNC Milling, Laser Cutting, Wire Cutting, Stamping, Electric Discharge Machining (EDM), etc. |

| Materials |

1). Aluminum: AL 6061-T6, 6063, 7075-T, etc

2). Stainless steel: 303, 304, 316L, 17-4(SUS630), etc

3). Steel: 45#, Q235, Q345B, etc

4). Titanium: TA1, TA2/GR2, TA4/GR5, etc

5). Brass: C36000 (HPb62), etc

6). Copper, bronze, POM, Acrylic, PC, etc |

| Surface Treatment |

Sandblasting, Anodize, Zinc/Nickl Plating, Polish |

| Processing Technology |

CNC machining parts, turning/milling process |

| MOQ |

1pcs |

| Lead Time |

Sample: 3-10 days

Mass Production: within 10-25 days after receiving the deposit |

| Package |

1) pp bags + carton or wooden case

2) according to customers' requirements

3) negotiable |

| Payment Terms |

T/T, Paypal |

CNC Machining Points

(1) For the current economic CNC lathes in China, the ordinary three-phase asynchronous motor is generally used to realize stepless speed change through the frequency converter. If there is no mechanical deceleration, the spindle output torque is often insufficient at low speed. If the cutting load is too large, it is easy to be stuffy. The car, but some gears with gears on the machine solve this problem very well.

(2) As far as possible, the tool can complete the machining of one part or one work shift. In particular, the large-piece finishing should pay attention to avoiding the middle of the tool change to ensure that the tool can be processed in one time.

(3) When using CNC machine to turn the thread, use high speed as much as possible to achieve high quality and efficient production.

(4) Use G96 whenever possible.

(5) The basic concept of high-speed machining is to make the feed exceed the heat conduction speed, so that the cutting heat is discharged along with the iron filings to isolate the cutting heat from the workpiece, ensuring that the workpiece does not heat up or heat up. Therefore, high-speed machining is very high. The cutting speed is matched with the high feed and the smaller backing knife is selected.

More about CNC Machining

CNC Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders. The CNC in CNC Machining stands for Computer Numerical Control.

On the surface, it may look like a normal PC controls the machines, but the computer's unique software and control console are what really sets the system apart for use in CNC machining.

Under CNC Machining, machine tools function through numerical control. A computer program is customized for an object and the machines are programmed with CNC machining language (called G-code) that essentially controls all features like feed rate, coordination, location and speeds. With CNC machining, the computer can control exact positioning and velocity. CNC machining is used in manufacturing both metal and plastic parts.

First a CAD drawing is created (either 2D or 3D), and then a code is created that the CNC machine will understand. The program is loaded and finally an operator runs a test of the program to ensure there are no problems. This trial run is referred to as "cutting air" and it is an important step because any mistake with speed and tool position could result in a scraped part or a damaged machine.

There are many advantages to using CNC Machining. The process is more precise than manual machining, and can be repeated in exactly the same manner over and over again. Because of the precision possible with CNC Machining, this process can produce complex shapes that would be almost impossible to achieve with manual machining. CNC Machining is used in the production of many complex three-dimensional shapes. It is because of these qualities that CNC Machining is used in jobs that need a high level of precision or very repetitive tasks.

Mass Production Process for CNC Machining

FAQ

Q: Can I get samples for testing?

A: We can offer free samples, but for big and high-value products, samples will be charged.

Q: Do you accept retail orders? What is the MOQ required?

A: Yes, we accept retail orders. MOQ is negotiable, free to contact us for discussion.

Q:What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can do the reverse engineering or provideyou better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q: How much is the freight?

A: We will decide according to your mode of shipping and quantity, it needs you to provide us with a specific mode of transportation(by sea or air), which port or airport to arrive at.

Q: What will you do if we receive poor quality parts?

A: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!