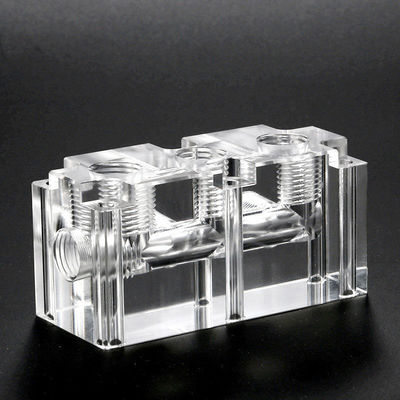

Acrylic CNC Milling Parts

Product Details

Poduct Name: Acrylic CNC Milling Parts

Material: Acrylic

Surface Treament: As machined

Size: Customized

Process Machine: CNC milling machine

Trade Terms: EXW

Proofing Time: 5-10 Days

Production Time: It depends on the structure and qty of the parts

Tokerance: ±0.05mm

Application: Equipment

Origin: Dongguan, China

CNC Machining Parts Description

| Manufacturing Process |

Milling, Turning, Grinding, Fast/Midium/Slow Wire EDM, Welding, Metal Plate, etc. |

| Material |

SUS, SPCC/SGCC, copper/brass, aluminum, ABS, plastic, rubber for option (according to customer's requirements for special material) |

| Surface Treatment |

Galvanized (zinc-plated, nickel-plated, chrome-plated, silver-plated),

powder coating/oil painting, polishing (mirror polishing, electrolytic polishing),

brushing, sand blasting, anodizing, etc. |

| Tolerance |

+/-0.01mm or special requirements |

| Package |

PE Bag, Paper carton box, plywood case/pallet/crate |

| Application |

Auto parts, electronic products, power supply, industry cabinet, construction, etc. |

| Drawing File Format |

Solidworks, Pro/E, Auto CAD, PDF, etc. |

| Features |

1. Customized Design

2. Sample Order Accepted

3. Short Delivery time

4. Competitive Prices

5. Long time quality Insurance

6. Professional after-sale services |

| Inspection |

IQC, PQC, FQC, OQA |

| Delivery Time |

3-30 days |

How CNC Milling Services Offered

The CNC Milling Services are offered by using a variety of CNC Milling Machines which are available in both horizontal and vertical models and they are capable for a varied components and operations.

Some of the common hardware comes attached with the machine to make the milling process easier and faster include:

- Spindle – This is the hardware that is responsible for rotating the chuck across the multiple axes

- Cutter – This hard is known for shaping the products

- Interface – This hardware is used for reading the CAD or CAM files efficiently and hence it controls the machine accordingly with the inputs of the operator.

- Chuck – This is hardware that is responsible for locking and securing the work pieces in place for precise machining.

The CNC Milling Services are offered in adherence to some of the core steps and this includes:

- Lunching the Milling Operation through interface

- Installation of the Milling materials as well as the cutter

- Inputting command for CAM or CAD files

- Inspecting the quality of final products after machining

Details on CNC Milling Services

CNC Milling Services is a part of CNC machining. CNC full form is Computer Numerical Controlled as the name suggests these machining services uses computer programmed code also termed as G code on these high accuracy machines to provide perfect designs by using varied variety of tools for cutting and removing the material. Common types of CNC machines are lathes, Vertical or Horizontal milling machines and routers.

Skilled Technician or machinists is required to successfully perform CNC machining. The person should be an expert in CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) software, as the programme is created using these software. G-Code is created based on this programming which will further instruct machine on how fast it needs to move the tool and where the tool should make a cut on the work piece. This G-code works in 5-Axis coordinate system.

With the introduction of CNC, the way machine parts are made and process to make has undergone a revolutionary change. Due to these changes the end result of your product is more accurate and made with more precision. Hence the outsourcing of these services is not frowned upon as you are getting better and accurate results. CNC milling services are similar to CNC drilling, in this machinist can make shapes by cutting the material in 5 axis coordinate system thus resulting in end products which cannot be made using old traditional methods that is manual methods.

Application of CNC Milling Parts

FAQ

Q: What is the shipping method?

A: For engineering samples we will send out by international express service or by air. For mass-production, it depends on weight and volume, usually by air or by sea.

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes. We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Q: How to contact sales person?

A: Please send us inquiry or e-mail directly. Or you can talk with us online by trademanager, skype, whatsapp, WeChat, etc.

Q: What's kinds of information you need for a quote?

A: Kindly please provide the product 2D drawing with PDF or DWG format and 3D drawings with STEP or IGS or X_T format, and other requirements like: surface treatment, quantity...etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!