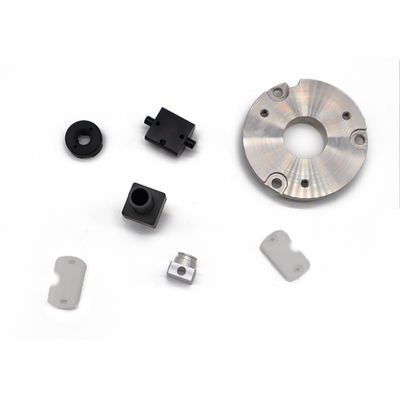

Mechanical Parts CNC Machining Service

Product Details

Product Name: Mechanical Parts CNC Machining Service

Material: Stainless Steel/Steel/Plastic/Aluminum

Process: CNC machining(turning, milling, drilling)

Surface Treatment: Polishing, sandblasting, anodizing, brushing, powder coating, electroplating, zinc plating, silk-screen

Tolerance: ±0.03mm

Quality control: 100% check before shipment

Drawing format: PDF/DWG/IGS/STP

Delivery: By DHL, FEDEX and so on

Term of Payment: 30% deposit when order, 70% before shipment

Trade Terms: FOB, CIF, EXW

CNC Machining Parts Description

| Manufacturing Process |

Milling, Turning, Grinding, Fast/Midium/Slow Wire EDM, Welding, Metal Plate, etc. |

| Material |

SUS, SPCC/SGCC, copper/brass, aluminum, ABS, plastic, rubber for option (according to customer's requirements for special material) |

| Surface Treatment |

Galvanized (zinc-plated, nickel-plated, chrome-plated, silver-plated),

powder coating/oil painting, polishing (mirror polishing, electrolytic polishing),

brushing, sand blasting, anodizing, etc. |

| Tolerance |

+/-0.01mm or special requirements |

| Package |

PE Bag, Paper carton box, plywood case/pallet/crate |

| Application |

Auto parts, electronic products, power supply, industry cabinet, construction, etc. |

| Drawing File Format |

Solidworks, Pro/E, Auto CAD, PDF, etc. |

| Features |

1. Customized Design

2. Sample Order Accepted

3. Short Delivery time

4. Competitive Prices

5. Long time quality Insurance

6. Professional after-sale services |

| Inspection |

IQC, PQC, FQC, OQA |

| Delivery Time |

3-30 days |

The Difference Between 3D Printing and CNC Machining

Scope of production. The machinable range of 3D printing technology is larger than that of CNC manufacturing. 3D printing has a high degree of freedom and can make difficult or impossible geometries that cannot be done by CNC.Development level. The CNC machining industry has a mature set of standards, including spindles, tool interfaces and control systems, but there is no such established standard in the 3D printing field.Product volume. 3D printing is difficult to make very large pieces, but CNC can handle it.Process type. 3D printing is an additive manufacturing method that builds up models, while CNC is a subtractive manufacturing process that continuously cuts and removes the entire raw material.

We can’t say that direct additive manufacturing is not good or CNC machining is not good, but for manufacturing companies, the advantages brought by CNC machining are higher than additive manufacturing (except for companies that sell customized products).

Therefore, I think CNC machining will still be in the manufacturing industry, and the processing industry will maintain its unshakable position.

CNC Machining Center Tap Processing Method

It is suitable for threaded holes with small diameters or low hole position accuracy requirements. Generally, the diameter of the threaded bottom hole drill is close to the upper limit of the diameter tolerance of the threaded bottom hole, which can reduce the machining allowance of the tap and reduce the load of the tap. Improve the service life of the tap.

We need to choose the appropriate tap according to the material to be processed. The tap is relative to the milling cutter and the boring cutter.

It is very sensitive to the material to be processed. Taps are divided into through-hole taps and blind-hole taps. The front-end guide of through-hole taps is long for front chip removal. When processing blind holes, the processing depth of the thread cannot be guaranteed, and the front-end guide of blind holes is short for rear chip removal, so pay attention to the difference between the two. When using a flexible tapping chuck, pay attention to the diameter of the tap shank and the width of the square to be the same as that of the tapping chuck. The diameter of the tap shank for rigid tapping should be the same as that of the spring. The jacket diameter is the same.

The programming of the tap machining method is relatively simple, all of which are fixed modes, and it is enough to add parameter values. It should be noted that different numerical control systems and subprogram formats are also different, so the representative meaning of the parameter values is different.

CNC Machining Advantage

FAQ

Q: Can I get samples for testing?

A: We can offer free samples, but for big and high-value products, samples will be charged.

Q: Do you accept retail orders? What is the MOQ required?

A: Yes, we accept retail orders. MOQ is negotiable, free to contact us for discussion.

Q:What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can do the reverse engineering or provideyou better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q: How much is the freight?

A: We will decide according to your mode of shipping and quantity, it needs you to provide us with a specific mode of transportation(by sea or air), which port or airport to arrive at.

Q: What are the elements of your quotation?

A: Drawings or samples, materials, surface treatment and quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!